Reference: 4,5mm air-18-530-11600

Brand: ISB Precision

Reference: 4,5mm air-18-530-11600

Brand: ISB Precision

Reference: 22 L.R-20-550-11600

Brand: ISB Precision

Reference: 6,35 Brown-25-550-15230-3

Brand: ISB Precision

Reference: 22 Hornet-30-650-15230-3

Brand: ISB Precision

Reference: 410-25-750-15230-3

Brand: ISB Precision

We are one of the leading Czech manufacturers of the barrel blanks. We are constantly modernizing our technologies and acquiring new machines to meet the demanding requirements for our products. We strive for long-term business relationships with our customers and offer consistent quality and delivery times.

We deal with the development, production and modification of sporting and hunting weapons. We draw on the long-term experience of our company´s key employees in this highly sophisticated field of activity, as well as on cooperation with experts in this specific activity.

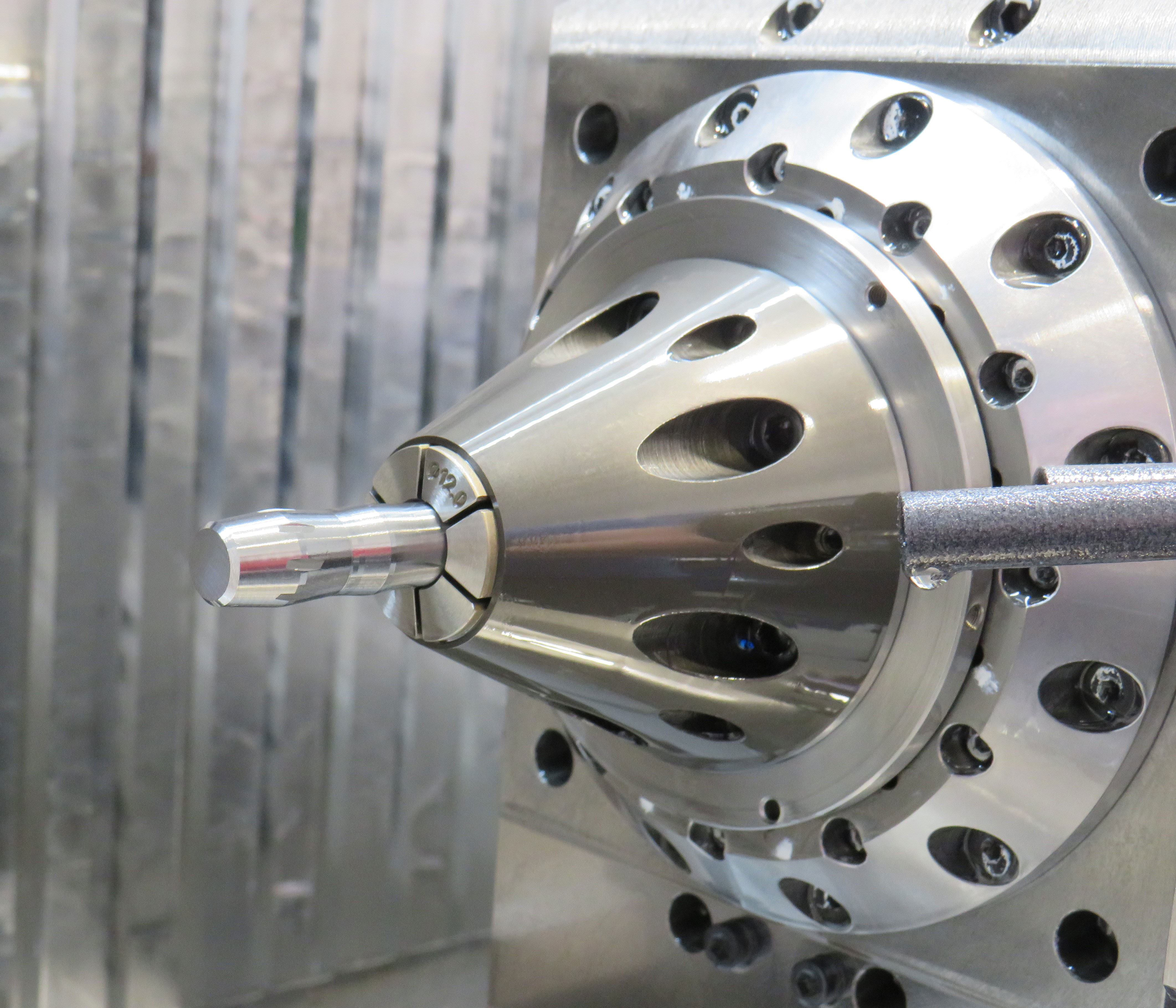

The production of blanks consists of four main operations: deep drilling, reaming, honing and grooving.

Barrel blanks for airguns and floberts:

Barrel blanks for pistols, revolvers and rifles:

By effectively leveraging and adhering to automation technology, our team provides innovative partnership solutions based on your unique needs.

We use third-party cookies to improve your browsing experience, analyze website traffic and customize content, advertisements.Find out more.